563-387-7315

- Home

- Power Tools & Accessories

- Lathes & Accessories

- Turning Tools

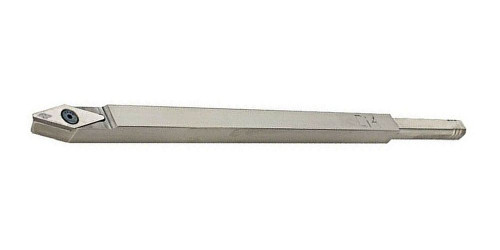

- Easy Wood Tools 7600 Mini Easy Detailer, Unhandled

Easy Wood Tools 7600 Mini Easy Detailer, Unhandled

Easy Wood Tools

Was:

Now:

$74.99

(You save

)

- SKU:

- ewt-7600

- UPC:

- 811269760006

- Width:

- 2.00 (in)

- Height:

- 10.00 (in)

- Depth:

- 4.00 (in)

- Shipping:

- Calculated at Checkout